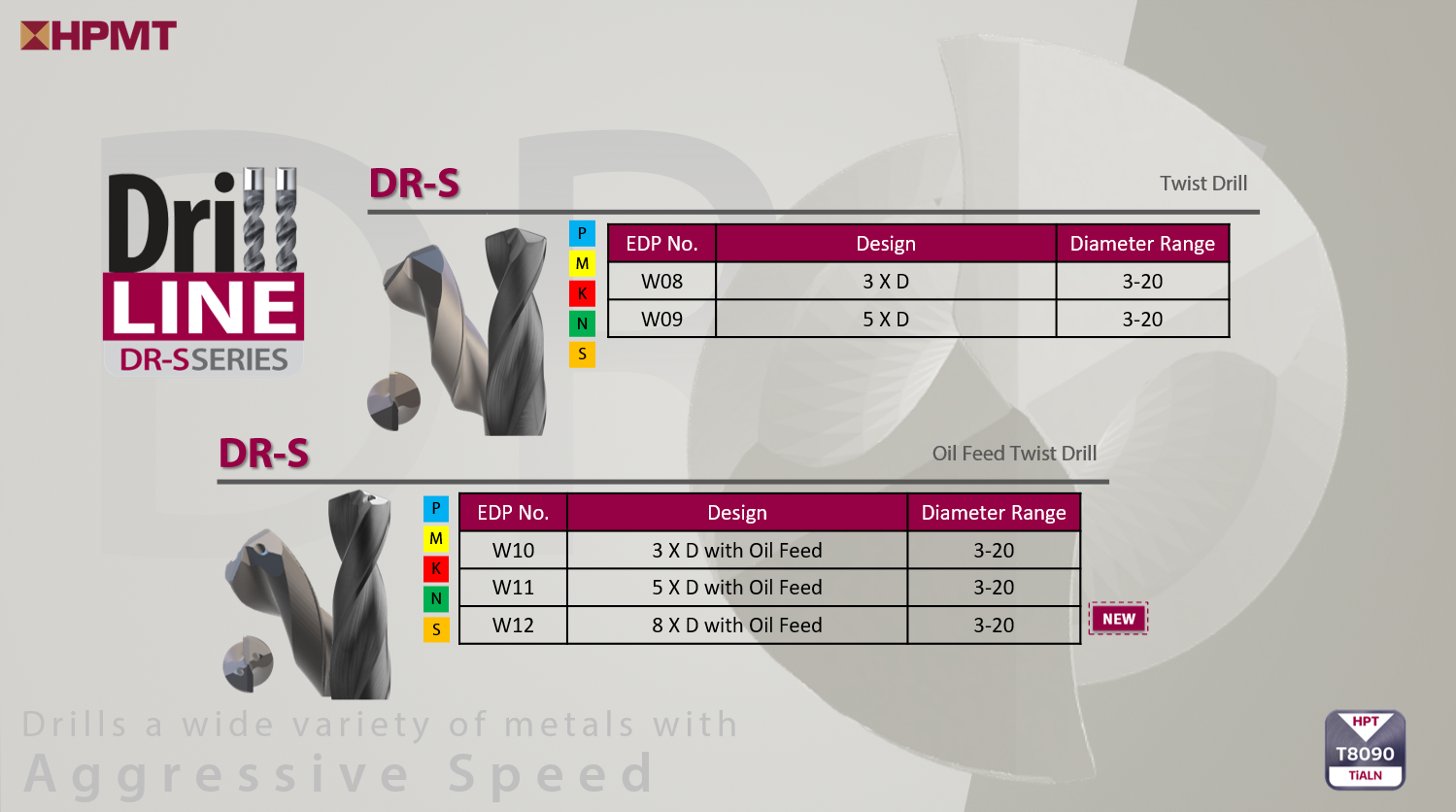

New DR-S variant, W12 with oil-feed

New DR-S variant, W12 with oil-feed

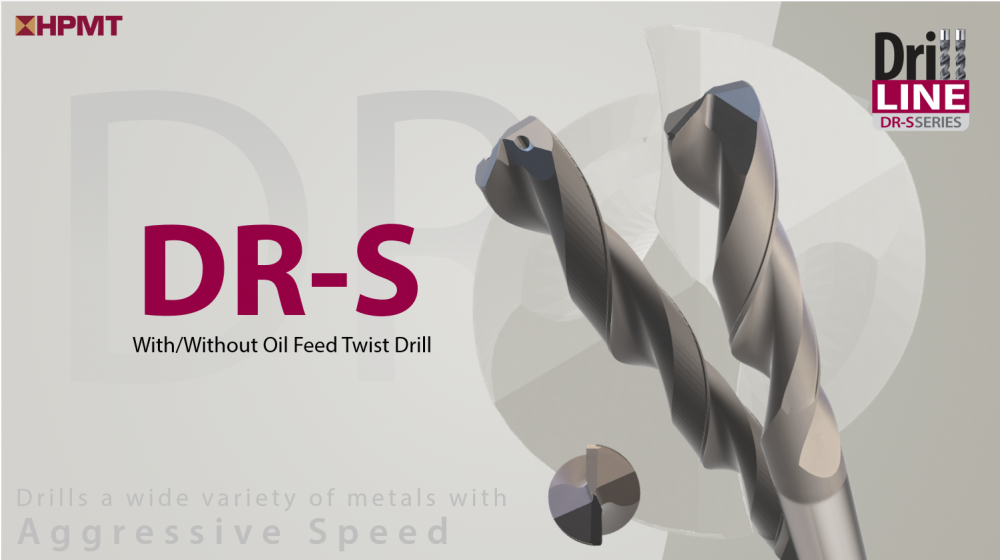

The new variant of our universal drill DR-S with internal coolant or "oil-feed" is now available.

To your advantage, we are now pleased to offer the new variant of our universal drill DR-S with internal coolant or "oil-feed".

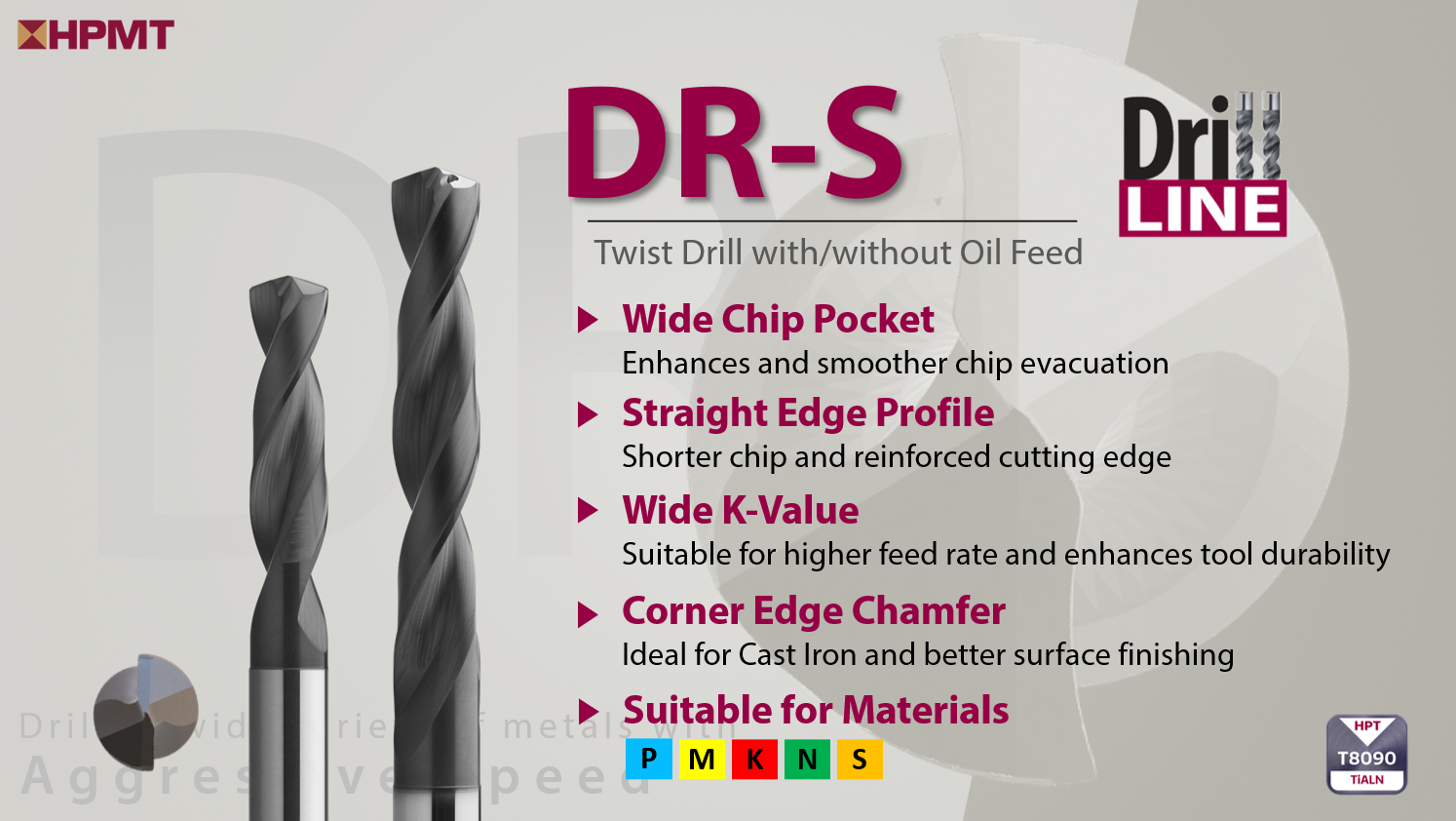

Having a 140º point angle increases cutting action and produces a sharp chisel edge on the drilling point. These types of drill points are self-centering and are the most durable types of drill points

The uniform distribution of cutting force and oil out of the hole improves chip evacuation, resulting in better surface quality and longer tool life.

Other Features & Benefits includes:-

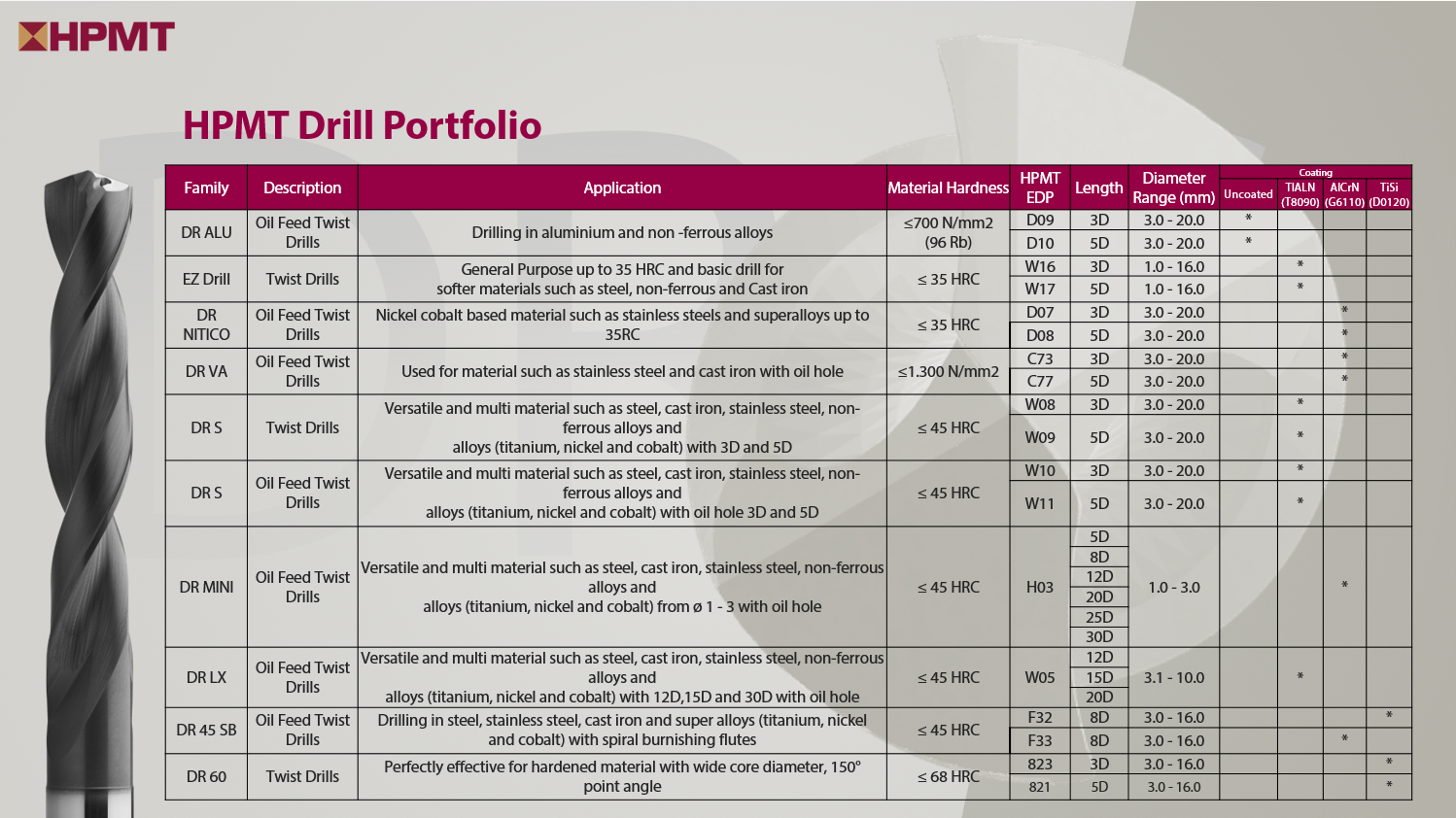

The DR-S is just one of the many drills we offer. The following is a list of all HPMT drills and their appropriate applications: