NiTiCo 30 DH for High-Performance Trochoidal Milling

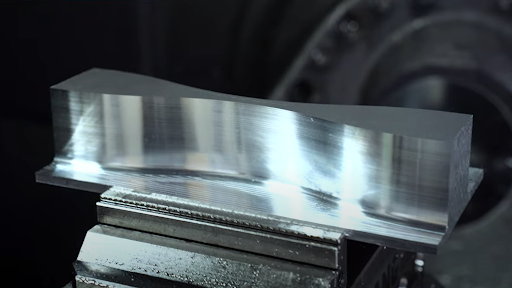

Trochoidal milling is a powerful machining strategy designed to maximize material removal while minimizing tool load and heat generation. It is particularly effective for stainless steel, titanium, and other tough alloys up to 45 HRC, which are widely used in aerospace, energy, Die & Mold, and general engineering industries.

However, engineers often face challenges with conventional tools in these applications, including rapid tool wear, inconsistent engagement, and limited productivity. Selecting a tool specifically engineered for trochoidal milling is critical to achieving high efficiency and reliable results.

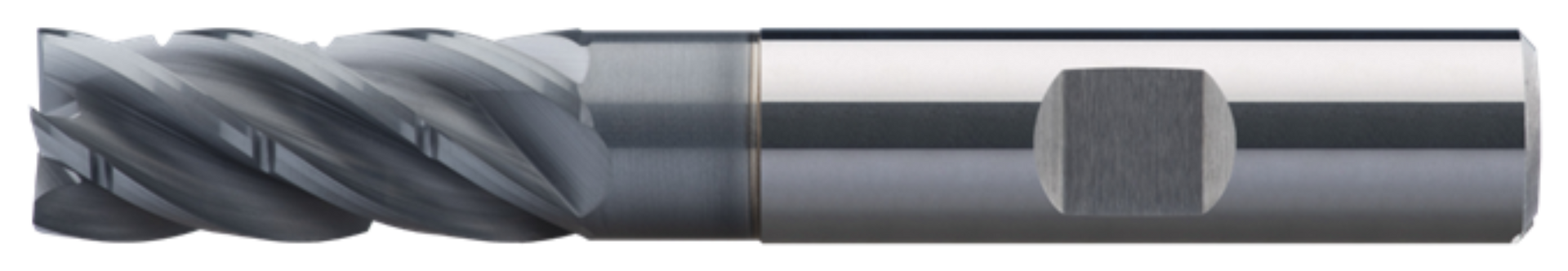

Key Design Advantages of NiTiCo 30 DH

High-Performance Geometry

NiTiCo 30 DH features a 5-flute design that delivers up to 25% higher feed rates compared to conventional 4-flute tools, achieving faster material removal without compromising rigidity. The additional flute improves edge contact while maintaining proper chip space, providing balanced load distribution for stable, high-speed trochoidal milling.

Its optimized geometry with integrated chipbreakers efficiently shears material into smaller chips, enhancing evacuation and reducing heat buildup in the cutting zone. This ensures smoother cutting, lower wear, and consistent performance even in deep cavities or interrupted cuts, making it ideal for stainless steel and titanium machining.

Advanced Geometry & Coating Synergy

The tool incorporates a differential helix design, where each flute has a slightly varied helix angle to disrupt harmonic vibrations common in traditional endmills. This feature minimizes chatter, improves surface consistency, and allows for stable high-speed machining.

Paired with its advanced coating technology, NiTiCo 30 DH maintains edge integrity under extreme conditions, improving wear resistance and heat control during long cutting cycles. The result is a combination of stability and durability that ensures predictable, repeatable machining performance.

Productivity-Driven Design

Engineered for high-efficiency material removal, NiTiCo 30 DH combines its geometry, helix design, and coating into a system optimized for maximum throughput. It maintains process stability under aggressive cutting parameters, reducing cycle time and tool changes while preserving dimensional accuracy. The outcome: higher productivity, lower operating costs, and consistent performance across all stainless steel and titanium applications.

NiTiCo 30 DH Product Range Overview

The NiTiCo 30 DH series is specifically designed for trochoidal milling across stainless steel, titanium, and other tough alloys (≤ 45 HRC). It is available in different configurations to meet diverse machining needs — whether the requirement is for internal coolant supply, extended reach, or standard length applications.

K65 | K67 – With Oil Hole and Chipbreaker

These variants feature an internal oil hole that delivers coolant directly to the cutting edge, improving heat dissipation and chip evacuation during deep or high-speed milling. The integrated chipbreaker geometry efficiently shears material into smaller, more manageable chips, preventing recutting and reducing cutting resistance.

This combination makes K65 and K67 ideal for continuous, high-efficiency milling in difficult materials like titanium or stainless steel, where thermal management is critical.

Standard Series – K50 | J89 | J90 (Without Oil Hole)

The standard-length versions are optimized for general-purpose trochoidal milling.

Without internal coolant channels, they are well-suited for open-area machining or setups where external coolant is sufficient. These models balance strength, rigidity, and accessibility, making them dependable for everyday operations in Die & Mold and general engineering environments.

Trochoidal Milling Performance Highlights

When it comes to trochoidal milling of stainless steel and titanium, tool performance directly impacts productivity, accuracy, and operational efficiency. The NiTiCo 30 DH is engineered to address these demands, delivering measurable improvements in durability, stability, and material removal. Key performance highlights include:

- Optimized for Stainless Steel and Titanium (≤ 45 HRC): Engineered to maintain cutting-edge sharpness and consistent material removal even when machining high-strength stainless steel and titanium alloys, ensuring precision and reliability in demanding Die & Mold and aerospace applications.

- Enhanced Productivity: The tool geometry and high-performance coating allow for higher feed rates and deeper engagement per pass, increasing material removal rates and reducing cycle time, which is critical in high-volume or complex machining operations.

- Stable Machining: Optimized flute spacing and geometric design provide stable engagement, reduce vibration, and minimize deflection, ensuring precise trochoidal milling with consistent accuracy and repeatability across all operations.

NiTiCo 30 DH is a tool built for engineers who demand productivity, reliability, and precision in trochoidal milling. Its combination of optimized geometry, high-performance coating, and durable construction allows for faster cycle times, extended tool life, and consistent machining results across stainless steel, titanium, and other tough alloys. Watch our video below and see it for yourself.

By choosing NiTiCo 30 DH, engineers can maximize throughput, reduce downtime, and maintain dimensional integrity—making it an indispensable tool in aerospace, energy, Die & Mold, and general engineering applications. Access the product leaflet here.

At HPMT, our mission is simple: to empower manufacturers with tools that deliver results. Contact us today to explore the full NiTiCo 30 DH lineup or speak to our technical team to find the right tool for your application.