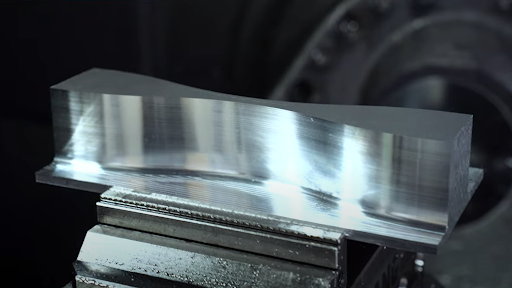

Maximizing Productivity and Durability in Aluminium Machining with XQ ALU (K41 & K43)

High-speed machining of aluminium and other non-ferrous materials is a cornerstone in industries like aerospace, automotive, and energy. Despite being softer than steel, aluminium can present significant challenges: chip accumulation, heat buildup, and tool wear, all of which can reduce productivity and compromise part consistency.

The XQ ALU series (K41 & K43) was engineered to meet these challenges head-on. With advanced DLC coating and precision-optimized geometries, these tools deliver high durability, stable performance, and measurable productivity gains in demanding Die & Mold operations.

What Makes XQ ALU (K41 & K43) Different?

DLC Coating (D0600)

The DLC coating dramatically extends tool life by resisting wear and reducing friction, enabling sustained high-speed cutting without premature edge degradation. This minimizes downtime from tool changes and ensures consistent performance throughout long production runs.

Optimized Geometries

The K41 and K43 endmills feature optimized cutting edges and flute designs, specifically for high-speed aluminium machining. These geometries reduce cutting forces, improve chip evacuation, and maintain stable engagement, allowing engineers to push feed rates while maintaining control and precision.

Polished Flute Design

The polished flutes promote smoother chip flow and reduce friction, which keeps the cutting edge sharper for longer. This design ensures stable, predictable performance across all operations, from roughing to finishing passes, maximizing uptime.

Performance Highlights

The XQ ALU (K41 & K43) tools excel in high-speed aluminium machining, providing engineers with substantial performance gains:

- Significantly higher productivity: Optimized geometry and cutting-edge design allow engineers to run faster feed rates while maintaining control, enabling more parts produced per cycle and improved overall throughput.

- Enhanced durability: The DLC coating ensures longer tool life, reducing the frequency of tool changes and minimizing downtime, which is critical in high-volume or continuous operations.

- Consistent and stable performance: Even across extended machining runs and complex geometries, XQ ALU maintains precision and dimensional integrity, ensuring predictable outcomes and reduced variability in production.

These design advantages translate directly into greater machining efficiency, lower operational costs, and reliable performance, helping engineers maximize productivity in demanding applications.

Real-World Application Case Studies

The XQ ALU (K41 & K43) series has shown its value across several industries. Here are just a few examples of how these tools are making a difference in real-world applications:

Automotive: The XQ ALU series allows engineers to machine lightweight aluminium engine blocks, transmission housings, and chassis components at high feed rates without compromising precision. Its durability and stable geometry minimize tool deflection and vibration, enabling longer uninterrupted production runs—critical for high-volume automotive manufacturing where cycle time and repeatability directly impact efficiency and cost.

Aerospace: For structural aluminium components, including wing brackets, fuselage elements, and landing gear housings, dimensional accuracy and consistency are paramount. XQ ALU tools maintain tight tolerances under high-speed conditions, enabling engineers to reduce secondary operations and avoid material distortion. The tools’ robust coating and optimized flute design ensure stable chip evacuation and heat management, which is especially important in thin-walled or complex 3D features.

Energy:

When machining aluminium components for renewable energy systems, power generation equipment, and electrical enclosures, productivity and reliability are essential. XQ ALU tools deliver predictable performance across extended cycles, allowing engineers to maintain consistent dimensional quality in high-volume or large-scale components. The combination of DLC coating and optimized geometry ensures long tool life, reduced downtime, and the ability to handle both roughing and semi-finishing operations efficiently.

Technical Specifications and Tooling Range

The XQ ALU (K41 & K43) series is available in two specific geometries to meet your machining needs:

Why Engineers Choose XQ ALU (K41 & K43)

For high-speed aluminium machining, efficiency and reliability are paramount. XQ ALU (K41 & K43) delivers up to 4.4× higher productivity, extended tool life through DLC coating, and consistent machining performance across all operations.

These tools allow engineers to maximize throughput, reduce downtime, and achieve predictable results, making them an essential solution for modern Die & Mold applications. Watch our video below and see it for yourself.

Get higher productivity and fewer tool changes in aluminium with XQ Alu. Access the product leaflet here.

At HPMT, our mission is simple: to empower manufacturers with tools that deliver results. Contact us today to explore the full XQ Alu lineup or speak to our technical team to find the right tool for your application.