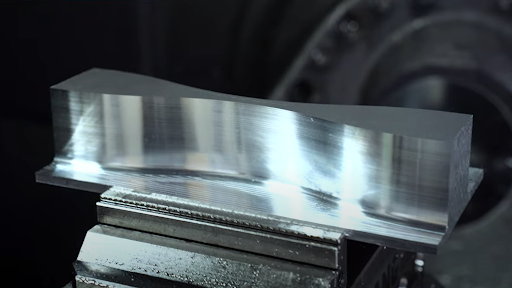

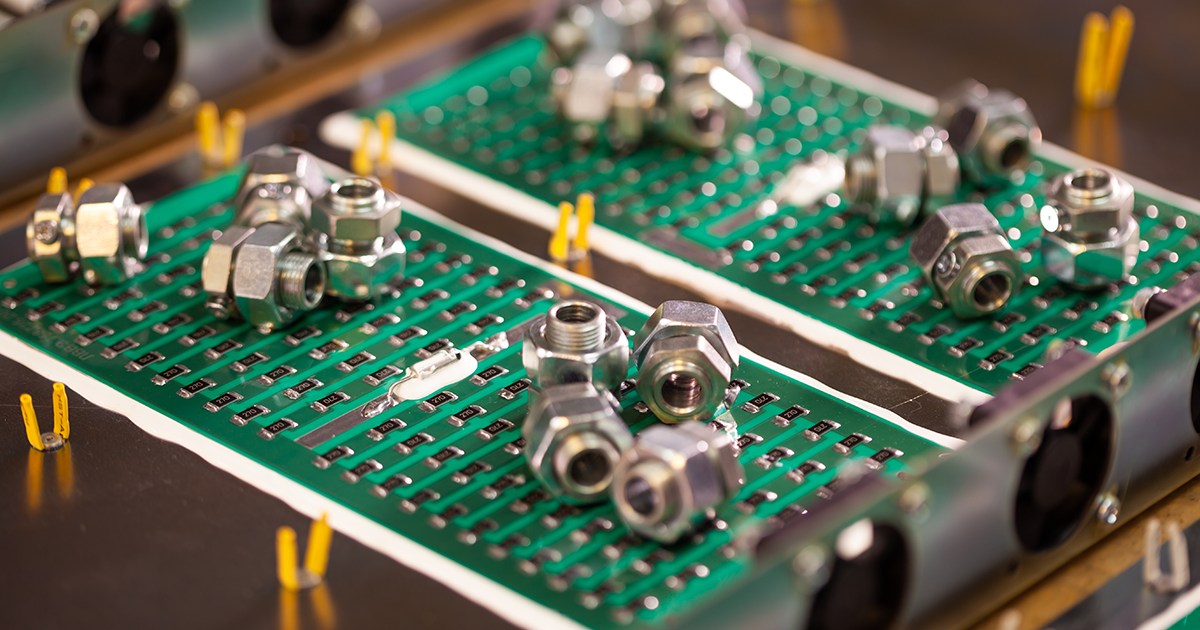

A handbook for a better machining experience

A handbook for a better machining experience

This year’s anniversary of the catalogue marks its 5th edition! This time around, we’ve added new exciting products and made some improvements to familiar favorites.

For those looking for a suitable cutting tool amongst our 2022 offerings, Catalogue E will be a great tool to come back to again and again on the path to a better machining experience.

We have also added on a special, live event to talk about all the new, exciting things. Sign up to hear all about it!.

Join us this 24th February to hear about the new additions and changes in the edition that will help you look for the tool you need today!

You can register for the LIVE webinar launch here: https://bit.ly/3o4v6bM

Remember to request your free Hard Copy by emailing us at info@hpmt-industries.com