The Ultimate Expert's Guide to Aluminium Drilling: Tips, Techniques, and Tools

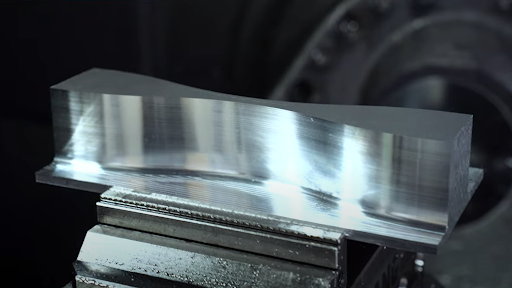

Aluminium is a versatile and widely used material in machining, due to its lightweight yet durable properties. From the aerospace to automotive sectors, mastering the precision drilling of aluminium is paramount for achieving superior end products. In this comprehensive guide, we will explore the tips, techniques, and tools necessary to master the art of aluminium drilling.

When it comes to drilling aluminium, using the right tools is crucial. Aluminium has unique characteristics that require specific machining tools designed for this material. Using improper tools can lead to poor results, including rough edges, burrs, and even damage to the material itself. To ensure the best outcome, it is essential to invest in high-quality machining tools specifically designed for aluminium drilling.

Types of Drilling Tools for Aluminium

There are several types of machining tools available for drilling aluminium. One of the most commonly used tools is the twist drill bit. Twist drills have flutes that help remove chips from the hole, preventing clogging and overheating. When choosing a twist drill bit for aluminium, opt for one with solid carbide, as they offer excellent heat resistance and durability.

Another popular type of drilling tool for aluminium is the step drill bit. Step drill bits have a conical shape with multiple steps of increasing diameter. They are ideal for drilling holes of various sizes in aluminium sheets or thin materials. Step drill bits also provide a smooth cutting action, reducing the risk of chipping or cracking the aluminium.

For more precision drilling, consider using a centre drill bit. Center drills have a pointed end and are often used to create a small indentation or starter hole before drilling with a larger bit. This helps prevent the drill bit from wandering and ensures accurate hole placement. Centre drill bits are particularly useful when drilling through thick aluminium plates or when working with curved surfaces.

Advanced Techniques for Precision Aluminium Drilling

To achieve precise and clean holes in aluminium, it is important to employ advanced drilling techniques. One technique is to use a drilling lubricant or cutting fluid. Applying a lubricant while drilling helps reduce friction and heat buildup, prolonging the life of your drilling tools and producing smoother holes. Be sure to choose a cutting fluid specifically formulated for aluminium to avoid any adverse chemical reactions.

Another technique is to use a peck drilling method. Peck drilling involves drilling a short distance into the material, then retracting the drill bit to remove the chips and cool down the tool. This process is repeated until the desired depth is reached. Peck drilling is especially effective when drilling deep holes in aluminium, as it prevents chip clogging and overheating.

When drilling through thick aluminium, it is beneficial to use a pilot hole. A pilot hole is a small-diameter hole drilled before using a larger drill bit. This technique helps guide the larger bit and reduces the chances of the drill bit wandering or the material cracking. Ensure the pilot hole is slightly smaller than the desired hole size to maintain accuracy.

Best Practices for Maintaining Aluminium Drilling Tools

To prolong the lifespan of your aluminium drilling tools and maintain their performance, it is important to follow the best practices for tool maintenance. Here are some tips to keep your tools in optimal condition:

- Clean your drilling tools after each use to remove any debris or metal shavings that may cause damage or affect performance.

- Store your tools in a dry and clean environment to prevent rust or corrosion.

- Regularly inspect your tools for any signs of wear, such as dull cutting edges or damaged flutes. Replace or re-sharpen them as necessary.

- Follow the manufacturer's recommendations for cutting speed, feed rate, and cutting depth to avoid overloading or damaging the tools.

- Use a suitable cutting fluid or lubricant when drilling aluminium to reduce friction and heat buildup

By implementing these best practices, you can ensure that your aluminium drilling tools remain in excellent condition and deliver consistent results.

Drilling aluminium requires precision, the right tools, and proper techniques. By following the tips and techniques outlined in this guide, you can achieve optimal results when drilling aluminium. Remember to invest in high-quality machining tools specifically designed for aluminium, employ advanced drilling techniques such as peck drilling and using a pilot hole, and prioritize safety throughout the process. By mastering the art of aluminium drilling, you can confidently tackle any project involving this versatile material.

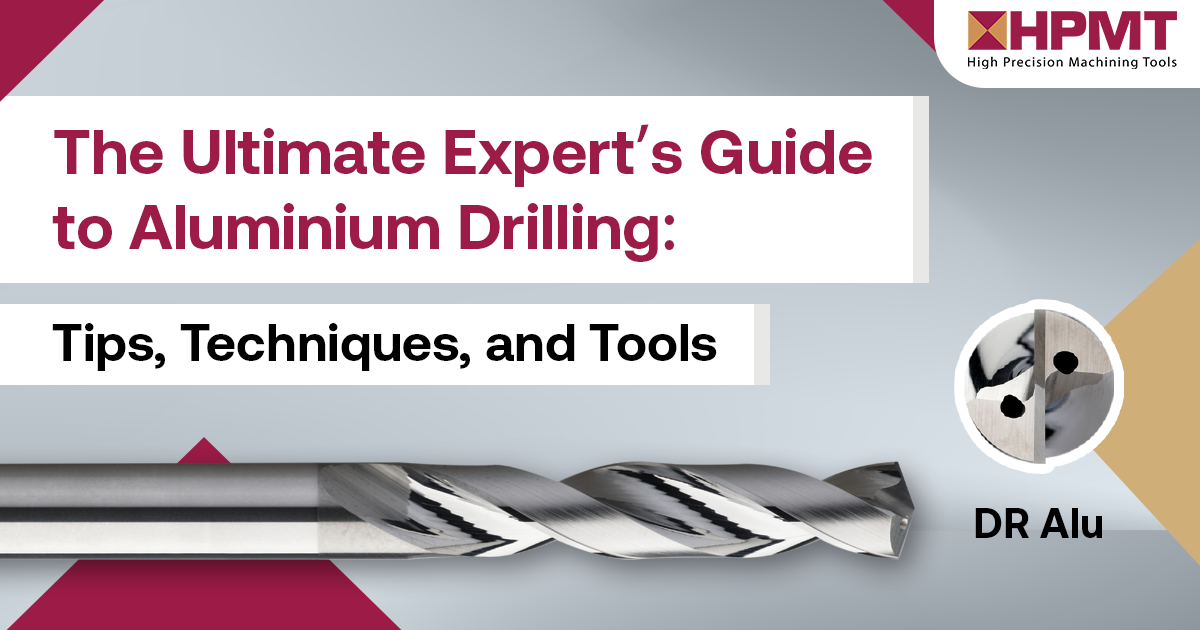

Introducing HPMT DR Alu Line

To further enhance your aluminium drilling experience, consider exploring the

HPMT DR Alu Line. The DR Alu is a high-performance drilling series specifically designed for non-ferrous materials such as aluminium, copper, zinc, and aluminium alloys. It is available in diameters from 3mm to 20mm and ensures exceptional performance and precise results. Curious how the HPMT DR Alu line can make aluminium machining easier? Explore its features and benefits below to unlock the secrets to a streamlined process.

List of Services

-

Self-Centering GeometryList Item 1

- Excellent hole quality without centre drilling operations

-

Varied Cutting EdgeList Item 2

- Maximum chip space for fast chip evacuation initial cutting point near the centre

-

Polished FlutesList Item 3

- Ensures fast, efficient chips evacuation and drastically reduces built-up edge

-

Oil Hole for High-Performance Drilling

- Increases cutting speeds and feeds by more than 30%

- Improves surface finish on the machined component

Learn more about the HPMT Alu Line

here.