Discover excellence with

Our Products

We offer a huge assortment of world-class solid-carbide endmills and drills for most machining operations, catering to the diverse needs of the manufacturing industries. We have the right tool for your application.

Discover the story behind our passion

About Us

As a global leader in high-precision solid-carbide cutting tools, we collaborate with customers from various industries to help them succeed. Our cutting-edge tools are designed to elevate your machining capabilities and deliver exceptional results across a wide range of industries.

Find the perfect tool for your project

TOOL ADVISOR

Whether it’s finding the right cutting tool for your application, the cutting parameters or the drawings to streamline your process, the new Tool Advisor is the go-to solution. Now more comprehensive and easier to use!

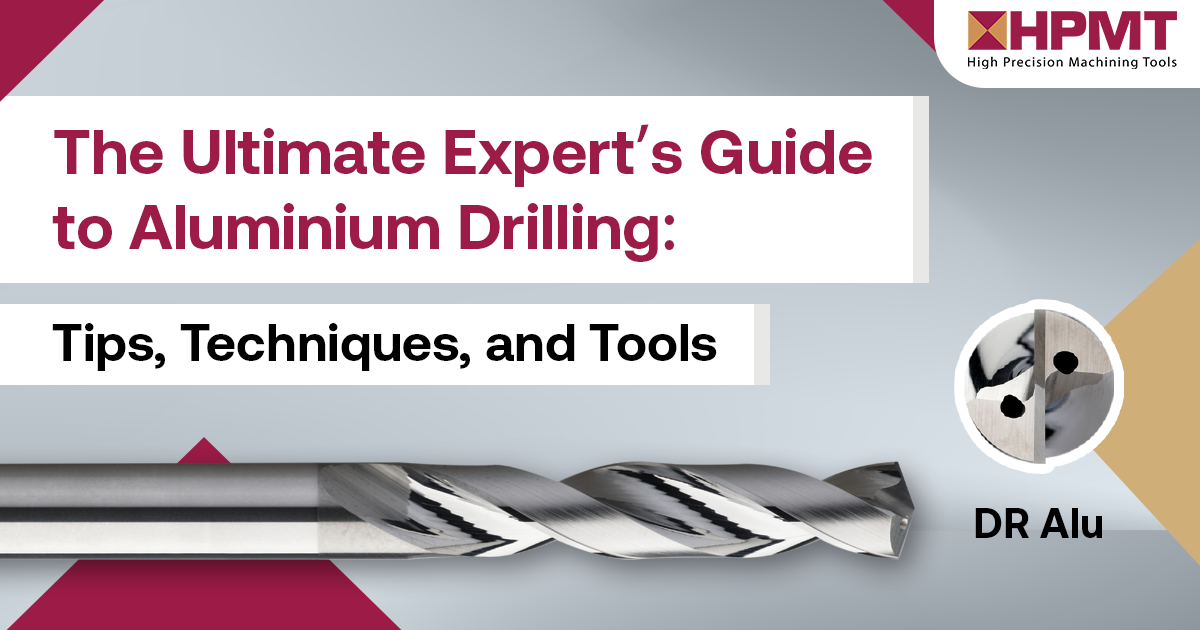

Don't miss out on the latest updates from HPMT

HIGHLIGHTS

Reach out to us

Contact Us Now

Discover how HPMT's cutting-edge solutions can elevate your machining performance and propel your business to new heights.

HPMT INDUSTRIES SDN BHD (405005-X)

5, Jalan Sungai Kayu Ara 32/39, Taman Berjaya, Seksyen 32, 40460, Shah Alam, Selangor Darul Ehsan, Malaysia

Tel: +603-58700098

Email: info@hpmt-industries.com

Our Products

Quick Link

All Rights Reserved | HPMT Industries Sdn. Bhd.